HydraFusion Strut Ram

The HydraFusion Struts were a game changer when PARATECH released the lifting/stabilizing device a few years back at FDIC. Rescuers can lift up to 10 U.S. Tons (9 metric tons) and to stabilize up to 20,000 lbs. with the tool. However, PARATECH’s HydraFusion Struts are not limited to just those two functions. The HydraFusion Struts can move metal!

I first ran across pictures of HydraFusion Struts used as ram from pictures that Brock Archer (Advanced Extrication) and Randy Schmitz ( Founder/Owner of Schmitz Mittz). Last weekend at Crunchtime Extrication, Paratech had one of their trailers at the training event and I had the chance to try a dash roll with a HydraFusion Strut. Take a look at the video below.

A few quick points:

- You can put the HydraFusion Strut in place to reduce any dash movement during reliefs cuts.

- HydraFusion Strut are portable and can be moved quickly to a vehicle hundreds of feet of the roadway.

- Depending on the length of the HydraFusion Strut used, strut extensions can be used to optimize dash movement.

- Using a HydraFusion Strut as a ram is an option, not always the option.

Heavy Rescue

Vehicle School Bus Under-ride Training Scenario

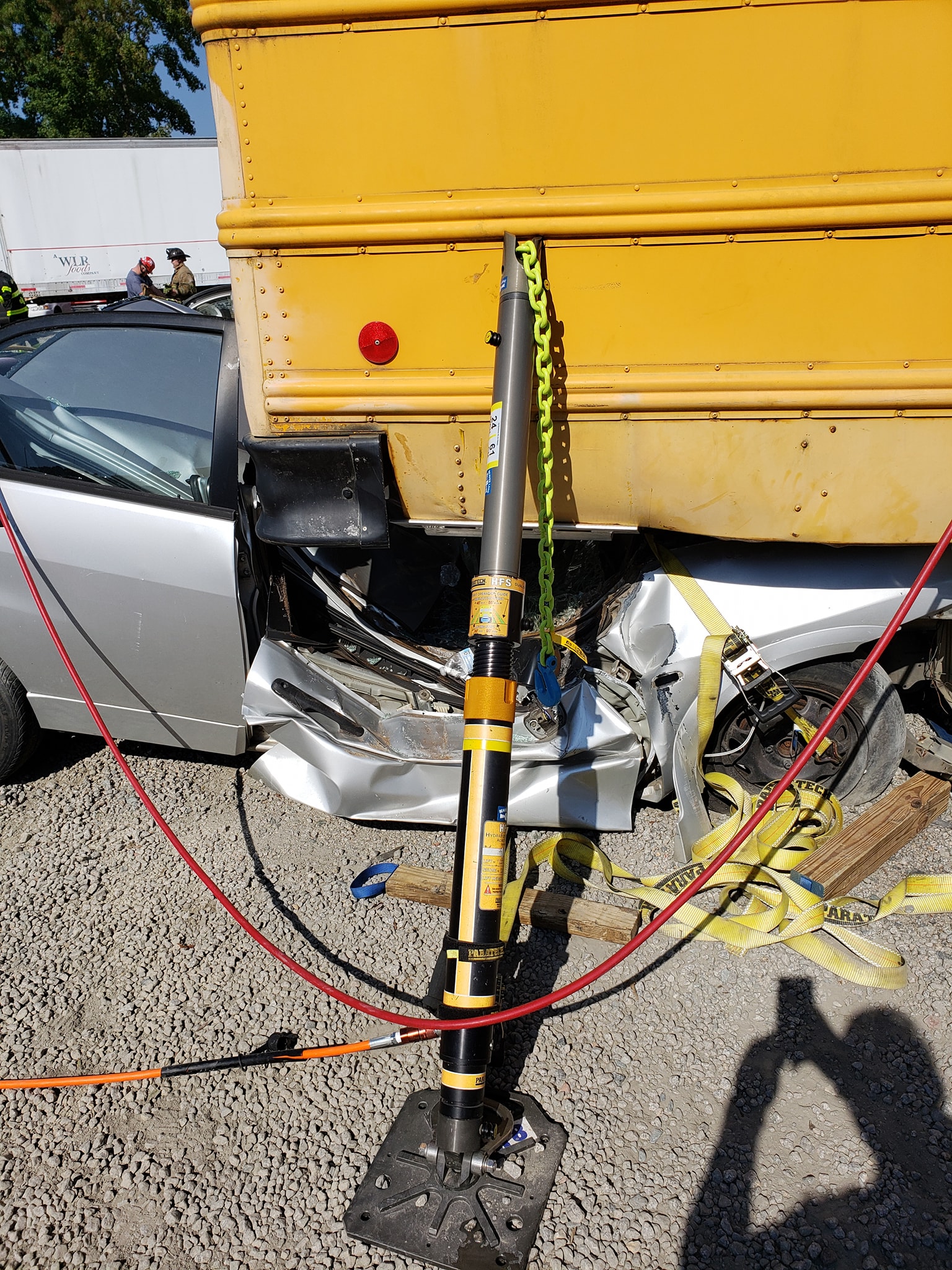

The Brothers at Beaver Lane Res8cue training with their PARATECH HydraFusion Struts on a training scenario for a vehicle that crashed underneath and school.

School Bus Under-ride

The Brothers at Beaver Lane Res8cue training with their PARATECH HydraFusion Struts on a training scenario for a vehicle that crashed underneath and school.

School Bus

Zero-emission Electric School Bus

There are about 480,000 school buses in the United States with about 95 percent of them run on diesel. How many will change to electric?

Electric School Bus

There are about 480,000 school buses in the United States with about 95 percent of them run on diesel. Currently, electric buses can be about two to three times as expensive as diesel models. However, school administrators would ultimately save about $2,000 on fuel and $4,400 in maintenance every year. Many school districts across the United States are adding zero emission or hybrid school buses into their fleets.

States across the country are looking into using their legal settlement funds from Volkswagen defeat device settlement to buy electric school buses. Just like electric passenger a decade again were few and far between, electric school buses are sparsely found in school district’s fleets.

School Bus Types

Below is a quick review of the 4 different types of school buses used in the United States.

:

| School Bus Configurations[1][2] (Images of Contemporary School Bus Models) |

||||

|---|---|---|---|---|

| Configuration | Type A |

Type B |

Type C |

Type D |

| Passenger Capacity (typical) |

≥10 typically 16-36 | ≥10 typically 30-36 | ≥10 typically 36-78 | ≥10 typically 54-90 |

| GVWR |

|

|

|

|

| Description |

|

|

|

|

Type A Electric School Bus

Blue Bird offers electric Type C & D configuration school bus.

Propane School Bus

Green and blue bumpers and other surfaces on school buses can identify a school as electric powered. However, green is also used for school buses powered by Compressed Natural Gas (CNG) and Propane.

School Bus Construction

The video below shows parts of Blue Bird Corporations manufacturing process. It will help you get an idea of where the strongest parts of the bus are located. Of course different manufacturers have varying methods.

It is important to know the construction of school buses, so we can attack them in the weakest areas first. Ultimately they are built like tanks to protect the passengers, which places the challenge on us as firefighters to gain access quickly and extricate rapidly.