Most rope rescues are highly technical events requiring in-depth knowledge of physics, engineering and safety. The challenge for rescuers is understanding the technicality and making it applicable to the rescuers on scene.

This can be accomplished through two approaches: training and equipment. The end goal should be a combination of both. To illustrate this, we’ll focus on the primary objective in rope rescue scenarios: How do we get down to the victim, and how do we get the victim back up?

Know your Team

Effective training requires some preliminary analysis. Let’s be realistic, every rescue company operates on a sliding scale of skill and knowledge. No matter how hard we pursue excellence, we have to accept the human factor.

There are individuals who understand all of the intricacies of mechanical advantage and force multipliers. There are also individuals who will continuously struggle with higher-end concepts such as these. This reality cannot be overlooked in the rope rescue environment.

So, we have to keep our eye on the big picture. The goal is not to train the entire team to be rope gurus. The goal is to create a cohesive team that can get the job done. Using our objective of accessing and rescuing the victim, we have to train on models that the entire team can perform.

Getting There

Let’s start with gaining access. There are two basic options: fixed brake and moving brake.

A fixed-brake system uses a descent-control device attached to an anchor. The rescuer is attached to a rope that is fed through the brake and lowered to the victim.

- Advantages: The rescuer has both hands free and does not have to possess a high level of rappelling skills. Many rescue organizations view this as a safer approach because it places the descent-control device in a much more static location than being attached to the rescuer.

- Disadvantages: There is a high propensity for delays due to communications regarding when and how the rescuer wants to move. Additionally, this requires the rope to be hauled back up if subsequent rescuers are needed. This can be time consuming.

A moving-brake system uses a descent-control device attached to a rescuer. The rescuer attaches a rope to an anchor and rigs the descent control device. In this application the rope is fixed and the descent-control device is moving.

- Advantages: The rescuer has complete control of his movement on the rope. This system may be faster to deploy and facilitates quicker transitions to get additional rescuers to the bottom.

- Disadvantages: This requires rescuers with rappelling skills including self-rescue, ascending, lock off tie offs, and mastery of the descent-control device being used.

Back to the Top

Once you’ve gained access to the victim, you need to have a versatile plan that allows you to convert quickly from lowering operations to hauling operations. Rescue events are full of unpredictable variables, so consider a hauling system that can convert back to lowering if needed.

The more versatility we have, the more capable we are of applying productive solutions. These lower and haul systems are of two basic varieties.

One is a traditional system commonly referred to as rack, pulley, hitch (RPH). This system applies a fixed brake with a hitch and pulley that can be converted to a mechanical-advantage system for hauling the victim up to safety.

- Advantage: This system uses common equipment and can be prebuilt for rapid deployment. There is a fair amount of debate about which hitch to use. The most common are the mariner’s hitch, the load-release hitch, and the radium-release hitch. I believe the load-release hitch provides the greatest versatility and sound engineering.

- Disadvantage: Your average firefighter will look at this system as an unsolved Rubik’s cube even with some basic training.

Changeovers under tension become very high risk if the appropriate techniques are not applied. The user-error factor can be exponential in the traditional system.

For lack of a better term, the second option is a specialized system. This system uses an auxiliary-equipment device designed to perform both hauling and lowering operations in a “fireman proof” manner. There several devices available that meet this criteria but let’s focus on the CMC MPD.

The MPD

This is a stand-alone device that is basically a one-directional pulley with an integrated friction-control device. It allows you to perform lowering and hauling operations with seamless transitions, even under tension. It also captures the progress of the load during hauling operations without any additional manipulations or attachments.

- Advantage: The MPD is extremely simple to operate. The cost of the device roughly correlates to the cost of a complete RPH system.

- Disadvantage: The MPD has had some minor performance issues in my experience with it in austere environments. The device is less forgiving in lowering applications than a brake bar rack when the rope is wet and has mud and debris on it. That being said, rescue crews should not let any device make you a one-trick pony. Redundancies should always be in place to convert to other options when the primary choice doesn’t work.

- Command and safety (operations officer and safety officer)

- Lower/Haul (team leader)

- Belay (team leader)

- Rescue (primary rescuer, back-up rescuer, EMS rescuer)

- Quantity, condition and location of victims.

- Desired anchors for mainline and belay operations.

- Potential alternative routes for access

- Probability or necessity for any special considerations (tripods or high directionals, floating anchors, packaging considerations, etc.).

Once these two options have been analyzed, based on crew capabilities and equipment cache, commit to one as the primary tactic and develop your pre-incident action plan. Train on it consistently and be critically encouraging.

Remember, the victim drives the rescue and we should always work to improve the safety and speed of our chosen tactics. One way to improve our speed and safety is to use prebuilt versatile systems.

Leadership Issues

The systems depicted in the Rescue Methods video tutorials are the prebuilt RPH and the CMC MPD. There are important discussion points on access variables using a moving brake approach. Mastering this type of approach to rope rescue will build confidence and muscle memory within your rescue crew.

The simplicity of prebuilt systems also allows you to delegate deployment of these systems to support personnel. This is vital in the overall scheme of the rescue event. Assigning key technical rescue personnel to leadership positions and highly technical positions is a must.

If your key personnel are sidelined performing basic operations, like edge protection and system construction, you will have a performance gap somewhere. The more technically savvy brains you have managing the essential pieces, the better the outcome will be. At a minimum, you should have key personnel assigned these sectors:

All other personnel can be support personnel assigned to those sectors. This is a general example that can grow in magnitude as the scenario dictates.

The operational commander should develop a primary and secondary action plan and communicate that plan to key personnel. This should be done without micro managing.

If the crew is well trained tactically and technically in primary and secondary applications, this communication process will be streamlined. All parties will know what to expect without having to spell out every detail. As a basic rule, I try to communicate some key criteria when functioning as an operational commander.

Once this information is conveyed, the team leaders can make appropriate choices regarding the specific types of systems, edge protection, and hardware and software because we have developed a prescribed method to our approach.

Get engaged. Click here to access the Rescue Methods blog and view the videos. Discuss it with your crew. Post your thoughts on the blog and interact with other rescue professionals.

Train hard. Those that call on us have great expectations often amidst insurmountable odds. Our desire should be to exceed those expectations every time.

This content provided in partnership with FireRescue1.com

Building Collapse

Houston Fire Department’s Trailer 11

Check out Houston Fire Department’s new Trailer 11 purchased from Metro Fire Apparatus Specialists, Inc. It’s packed for of Paratech equipment with room for more!

Houston Fire Department’s Trailer 11

Check out Houston Fire Department’s new Trailer 11 purchased from Metro Fire Apparatus Specialists, Inc. Check out the pictures below and make sure you follow the social media pages from Metro Fire Apparatus Specialists.

Overall Pictures

Compartments Pictures

Rear Pictures

Rope Rescue

Low Angle Rescue

Low Angle Rescue

Moving a patient up an embankment back to the roadway could be as simple as guiding them up. However, depending on the angle of the embankment, weather and soil conditions the safest method is with a stokes basket attached to a low angle rope hauling system. Paratech Monopod being used at a recent incident in Hunterdon County NJ.

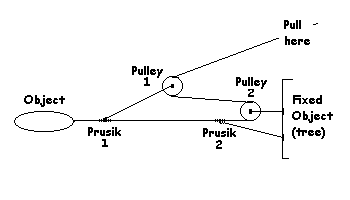

Z-Drag

Another easy to rig low angle system is a Z-Drag.

Rescue Rigs

Roswell GA Heavy Rescue Sutphen SVI-Trucks

This apparatus comes equipped with a Command Light Knight 2 series light tower, Carefree Mirage Lateral Arm Patio Awning, Resolve Space Saver fill station, Cab/Body Walk-Through Connection and packed full of Paratech Struts!

Roswell, GA Heavy Rescue

Roswell, GA Fire Rescue had a new heavy rescue built with a 22′ aluminum SVI-body mounted on a 20″ raised roof Sutphen Monarch chassis with a Cummins X12 500 HP engine. This apparatus comes equipped with a Command Light Knight 2 series light tower, Carefree Mirage Lateral Arm Patio Awning, Resolve Space Saver fill station, Cab/Body Walk-Through Connection and packed full of Paratech Struts!

- Features

- Specifications

- Drawings